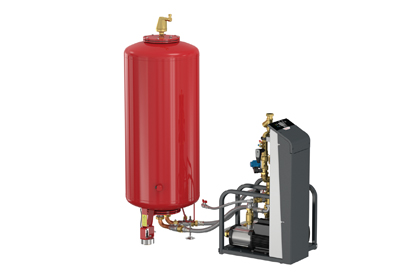

HVAC Pumps & Systems

FJ Group's Pump Division is among the pioneering units specializing in high-performance chilled water pumps, providing reliable and energy-efficient solutions for HVAC systems. The division offers a comprehensive range of pump types, including end-suction pumps, split-case pumps, vertical in-line pumps, and multistage pumps. We also provide custom solutions in terms of design and material to meet the specific demands of each application, ensuring durability, efficiency, and optimal performance across diverse projects and environments operation.